Total Sulfur Analyzer

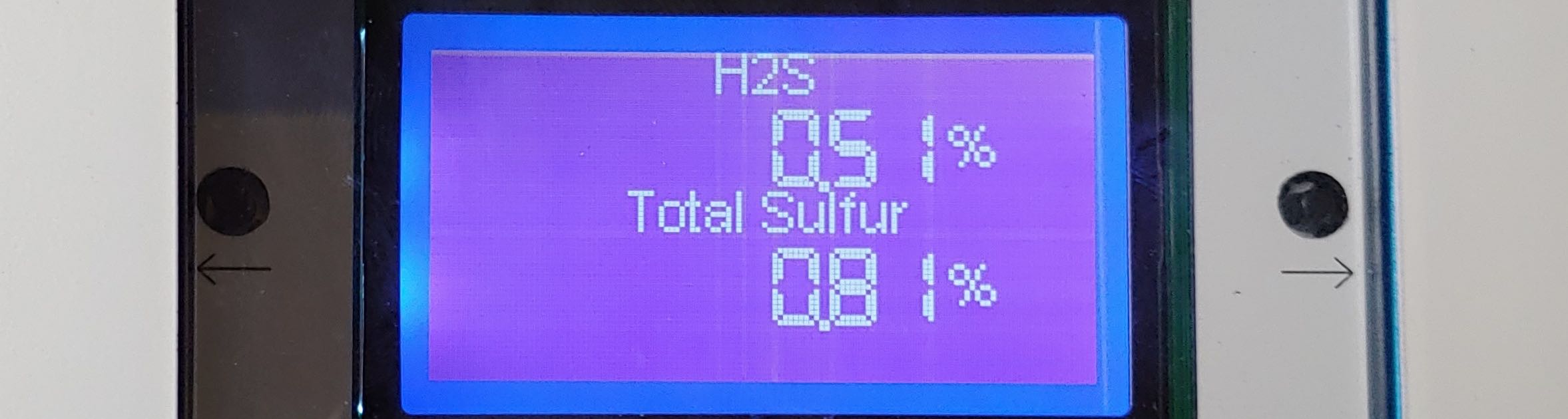

As a complement to our other analyzer systems, Reactor Resources offers a Dual Total Sulfur/H2S Analyzer (TSA) that continuously measures both the H2S and the Total Sulfur content of the the recycle gas. The analyzer wirelessly streams gas concentration data to our patented SmartSkid™ Injection System. This enables our clients to monitor H2S and mercaptan levels in real-time by viewing our cloud-based telemetry.

Benefits of Our Total Sulfur Analyzer System:

- Continuously measures both the H2S level and Total Sulfur Content of the recycle gas, providing critical data in real-time.

- By comparing these two values, you will know if there are non-decomposed mercaptans in the gas stream. Purging these compounds to the flare or fuel gas header can lead to excess SOx emissions since they will not be absorbed by your caustic scrubber.

- Eliminates the need for operations personnel to pull draeger tubes under fresh air (SCBA), freeing up manpower and greatly improving safety by reducing exposure risks.

- Allows optimization of spiking agent injection rates, saving on chemical costs and reducing compressor issues related to high gas density resulting from over-injection. High gas density can only be remedied by purging of sour gas to the flare (which can lead to sulfur emission exceedences) and bringing in fresh makeup hydrogen.

- Reduces startup time since you will be aware of H2S breakthrough within minutes of it occurring, allowing you to immediately proceed to the high temperature sulfiding plateau.

The savings this instrument provides can be significant since it minimizes the risk of exceeding stack SOx emissions.

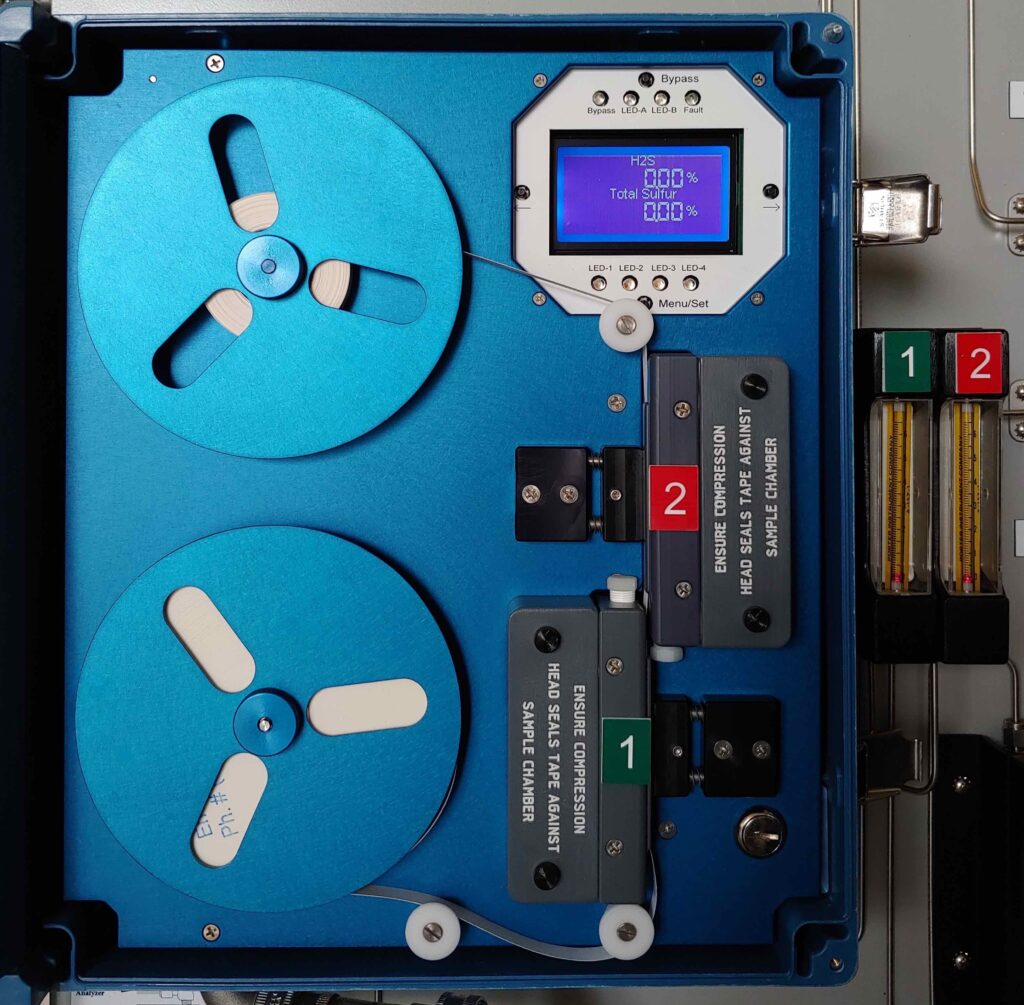

Pictured below is the inside of the TSA cabinet. The instrument uses two optical sensors to measure both H2S and Total Sulfur simultaneously.

Contact Us to discuss how our systems can minimize your sulfiding costs and startup time while improving operator safety.